OUR WORLD CLASS PRODUCTS & BRANDS

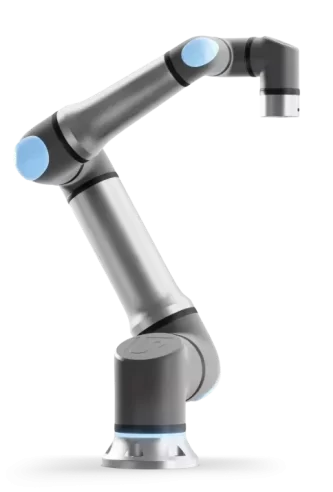

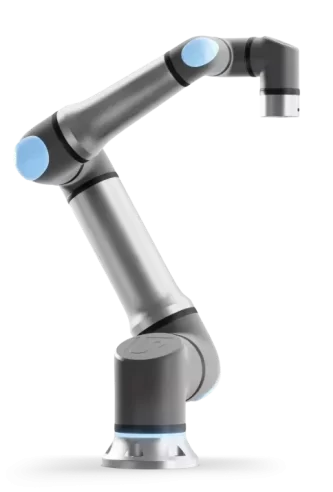

Universal Robots UR30

Performance in a Compact Size

- 30 KG payload

- 1300 mm reach

- 12 inch touchscreen with PolyScope graphical user interface

Need Help Finding the Right Component?

OUR WORLD CLASS PRODUCTS & BRANDS